What is SAP Digital Manufacturing Cloud (SAP DMC)?

Introduction

In today’s world, manufacturers are significantly redesigning their company’s operations to meet consumer demands in this New Normal era by establishing flexible supply chains, enabling remote operations, and permitting demand-based mass customization.

Businesses are looking for a solution in which they can meet the customer demands!

In this blog, we will look at how SAP is helping global organizations modernize their manufacturing processes in preparation for Industry 4.0 and the next-generation digital supply chain.

What is SAP Digital Manufacturing Cloud?

SAP Digital Manufacturing Cloud (SAP DMC) is a cloud-based manufacturing execution system (MES) that connects production and business in supply chain management. SAP DMC delivers global visibility across all plants by connecting top floor business systems to shop floor equipment.

Features of SAP DMC:

➔ Application of additional cloud services such as real-time analytics and machine learning to better understand and optimize operations

➔ Complete visibility of all production processes across all facilities.

➔ The scalability of the cloud-based MES system allows for rapid adaptation to needs.

➔ There is no investment in hardware or infrastructure, therefore high-maintenance decentralized server installations are outsourced.

➔ Ensured data and system availability with competent central server support

➔ Reports in real time on several vertical levels

➔ Planning, execution, and reporting tasks are all integrated.

➔ Production process orchestration in unified and hybrid system landscapes

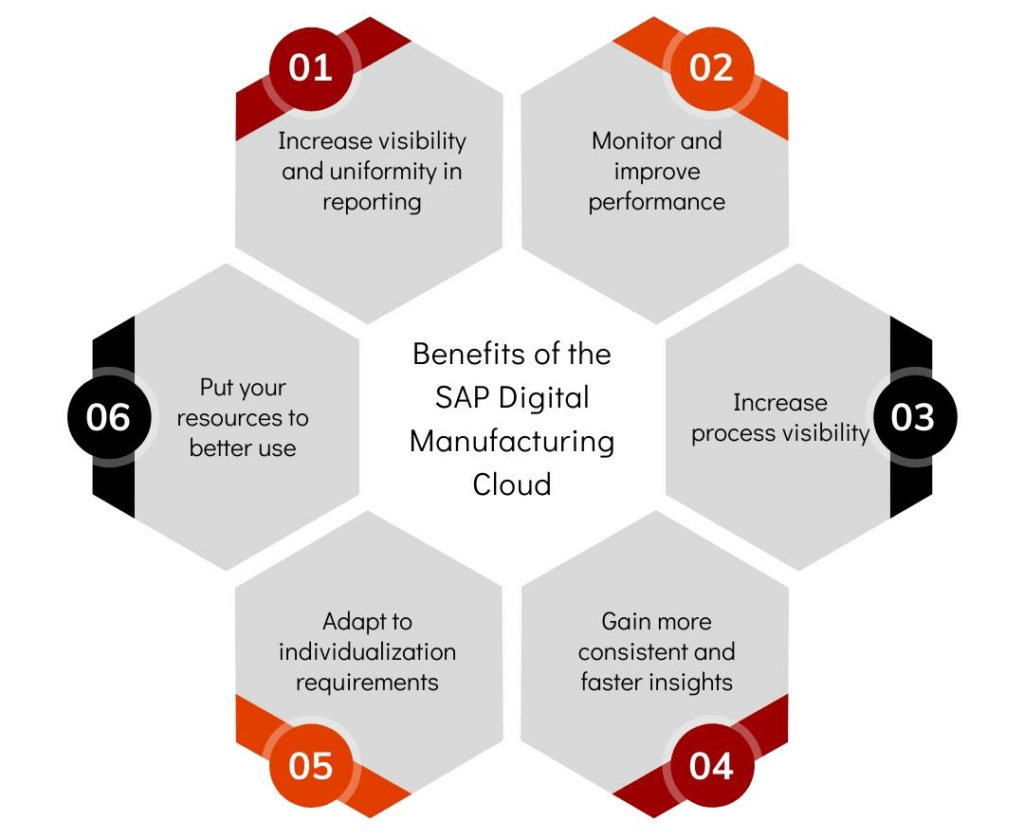

Benefits of the SAP Digital Manufacturing Cloud:

- Increase visibility and uniformity in reporting:

By combining numerous solutions and standards-based interfaces, you can collect data from various factory operations management (MOM) and automation systems.

- Monitor and improve performance:

Using straightforward, pre-configured analytics, enable key stakeholders to analyze global and plant-level manufacturing performance and related causes.

- Increase process visibility:

Better, more transparent production management is required to swiftly analyze and fix quality and productivity concerns while lowering warranty and liability risk.

- Gain more consistent and faster insights:

Accelerate root-cause analysis using powerful algorithms and machine learning to enable ongoing business improvement.

- Adapt to individualization requirements:

Meet market-of-one demand, deal with excessive product variability, boost customer satisfaction, and keep productivity, profitability, and quality standards stable.

- Put your resources to better use.

Maintain the seamless operation of MOM systems by optimizing the utilization of manufacturing resources, enhancing quality, and minimizing downtime.

Components of SAP Digital Manufacturing Cloud:

- SAP Digital Manufacturing Cloud For Execution(SAP DMCe)

- SAP Digital Manufacturing Cloud For Insights(SAP DMCi)

- SAP Digital Manufacturing Cloud For Manufacturing Network(SAP DMCn)

- SAP Digital Manufacturing Cloud For Resource Orchestration (SAP REO)

Now Let’s get into Detail for each module!

- SAP Digital Manufacturing Cloud For Execution(SAP DMCe):

The SAP Digital Manufacturing Cloud for Execution gives you a productive, secure, and integrated production control center. This enables you to gather and process data from the shop floor to the employees in real time. Production decision-makers have access to reliable, real-time data, allowing them to make more informed decisions.

Real-time Visibility: The SAP Digital production Cloud for Execution provides a centralized location for all important information required to plan and control production operations. This comprises information derived from a variety of sources, such as machine data, tool data, and inventory information.

Paperless Manufacturing: Paperless production is made feasible through intuitive user interfaces (UI). Digitized job papers and worker assistance assist you in lowering expenses, increasing agility, and increasing production.

Work Instructions: This module enables the generation, administration, and distribution of digital work instructions to operators and shop floor personnel. These instructions assure task execution uniformity and precision, which contributes to fulfilling the high quality standards required by clients.

Quality Management: DMCE enables the monitoring and management of product quality throughout the manufacturing cycle, resulting in fewer defects and conformity with industry standards, which is critical for meeting consumer demand for high-quality products.

- SAP Digital Manufacturing Cloud For Insights(SAP DMCi):

SAP Digital Manufacturing Insights (DMCi) provides a self-service platform for manufacturing analytics that is simple to use and intuitive. This technology delivers real-time visibility and insight into production capacity utilization, allowing for more informed business choices and increased efficiency through informed change.

Performance Metrics: The module provides extensive performance metrics, such as Overall Equipment Effectiveness (OEE) analysis and downtime analysis, to optimize equipment efficiency and minimize production downtime, assuring on-time customer deliveries.

Product Traceability: DMCI provides end-to-end product traceability, which is critical for regulatory compliance and effective recall management, protecting both quality and consumer trust.

Dashboards and KPIs are predefined: Contextualized data about your manufacturing processes helps in ensuring smooth operations and ongoing output improvement. Predefined dashboards and KPIs enable you to swiftly analyze and enhance your output.

- SAP Digital Manufacturing Cloud For Manufacturing Network(SAP DMCn):

SAP Digital Manufacturing Cloud for Networks (DMCn) is a cutting-edge, integrated digital platform that is revolutionizing and optimizing manufacturing processes within a networked environment.

Workforce Management: Manage the workforce efficiently by scheduling shifts, tracking attendance, and ensuring that staff have the appropriate skills for their tasks, all of which contribute to on-time delivery.

IoT connection: DMC improves connection by connecting machines, sensors, and industrial equipment. This allows for real-time data collection and analysis for enhanced operational efficiency and customer responsiveness.

- SAP Digital Manufacturing Cloud For Resource Orchestration(SAP REO):

SAP DMC REO is a scheduling and shift planning solution for industrial production managers. Its computerized scheduling helps in the identification of gaps in order plans and supports local knowledge by allowing modifications based on unanticipated occurrences such as machine or employee breakdowns.

Resource Planning: It assists manufacturers in properly planning and allocating resources by taking into account aspects such as machine availability, labor skills, and production priorities. This guarantees that the appropriate resources are assigned to the appropriate tasks at the appropriate time.

Identify High-Priority Jobs: With this display system, you can immediately and simply identify high-priority requests. The system delivers the information you need to successfully manage order prioritization. It helps you remain on top of things during your everyday work.

Last Thought:

SAP Digital Manufacturing Cloud modules DMCE, DMCI, and DMCn allow businesses to push the limits of their manufacturing processes. These modules are crucial to achieving manufacturing excellence as they provide real-time insights, allow for efficient resource allocation, and promote data-driven decision-making.

Take advantage of SAP Digital Manufacturing Cloud with KaarTech to take your manufacturing operations to new heights.

Contact us to know more!

FAQ’s

What is SAP Digital Manufacturing Cloud (SAP DMC)?

SAP DMC is a cloud-based Manufacturing Execution System (MES) that connects production and business systems, offering global visibility across all plants and enabling real-time analytics and machine learning to optimize operations.

What are the main components of SAP Digital Manufacturing Cloud?

The main components include SAP DMCe for execution, DMCi for insights, DMCn for manufacturing networks, and REO for resource orchestration, each focusing on specific functionalities to enhance manufacturing processes.

How does SAP DMC improve manufacturing operations?

It enhances operations by providing real-time visibility, paperless manufacturing, work instructions, quality management, performance metrics, product traceability, workforce management, IoT connection, resource planning, and prioritizing high-priority jobs.

What benefits can businesses derive from using SAP Digital Manufacturing Cloud?

Businesses can gain increased visibility and reporting uniformity, monitor and improve performance, enhance process visibility, attain faster insights, adapt to individualization requirements, and optimize resource utilization for seamless operations.