SAP AI Core: Sound-Based Predictive Maintenance

Happy to see you in Part 3 of our blog on SAP’s AI and Sustainability Solution!!

Part 2 of the blog is mainly focused on SAP AI Core Key Components and Machine Learning Workflow. Willing to read it? Here is the link!!

Let’s focus on Part 3.

Ever pondered whether devices could “hear” how well they were doing?

To get you curious, consider these three questions:

- Have you investigated the field of auditory-based predictive maintenance?

- Did you know that certain sound patterns can be used by machines to signal when they need maintenance?

- And do you know what special advantages sound-based predictive maintenance has over traditional approaches?

In this blog, we explore the intriguing nexus where machinery and artificial intelligence collide, and sound becomes a language. Learn how machines can understand their own sounds, which is bringing in a new era of proactive intervention.

Discover the unique benefits of sound-based predictive maintenance, which are changing the game in predictive maintenance by guaranteeing effectiveness, reducing downtime, and changing the way we maintain complex equipment.

Predictive Maintenance

By using data, sensors, and machine learning, predictive maintenance is a proactive strategy that foresees equipment failures before they happen. It increases overall operational efficiency by optimizing maintenance schedules, decreasing downtime, and extending the lifespan of machinery through the analysis of real-time data and historical patterns.

Sound-based predictive maintenance

Installing sensors on machinery and gathering acoustic data is the first step in the sound-based predictive maintenance process using IoT sensors. Machine learning algorithms examine sound patterns to learn typical operating sounds during the training phase.

By deploying these trained models to Internet of Things devices, real-time monitoring, anomaly detection, and maintenance demand prediction are made possible. This improves industrial efficiency by optimizing equipment performance and reducing downtime.

Resources in SAP AI Core

The below-mentioned ones are the resources in SAP AI Core:

- SAP AI Core Tenant

- Docker Registry

- Data Storage

- Git Repository

In SAP AI Core, the tenant is the dedicated environment where AI services are deployed and managed. The Docker registry stores containerized applications, ensuring consistent deployment across environments. Data storage manages the storage of AI models, datasets, and related information. The Git repository facilitates version control for collaborative development.

The SAP AI Core tenant provides a segregated space for AI services, promoting secure and organized development. The Docker registry streamlines deployment by encapsulating applications and dependencies in containers, ensuring portability and reproducibility.

Data storage supports efficient management of diverse datasets and models, which is crucial for AI workflows. The Git repository enhances collaboration by enabling version tracking, branching, and merging in the development process.

Together, these resources within SAP AI Core create a robust ecosystem for developing, deploying, and managing AI applications with efficiency and scalability.

Use case: Sustainable Smart Factory App

A sustainable smart factory app integrates eco-friendly practices into manufacturing processes. It optimizes resource usage, reduces waste, and leverages technology like IoT and AI for efficient operations. This app aligns with sustainability goals, fostering environmentally conscious and technologically advanced manufacturing practices for a greener industrial future.

The main purpose of the Sustainable Smart Factory Application was to

- Monitor day-to-day operations

- Recording energy consumption

- AI models score on live sensor data

- Placing proactive maintenance orders in SAP S/4HANA

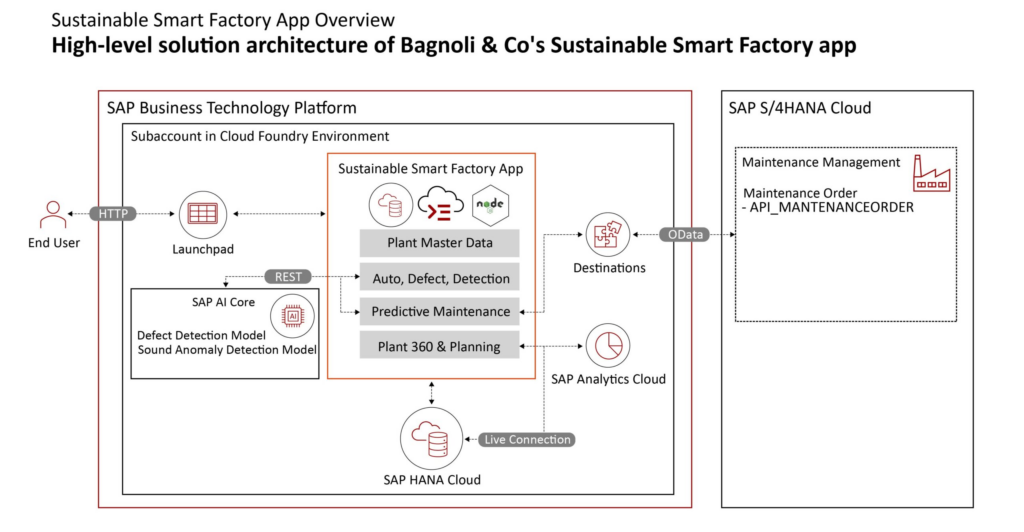

High-level solution architecture

A comprehensive and sustainable approach to manufacturing is ensured by the high-level solution architecture of the Sustainable Smart Factory app, which is made to seamlessly integrate multiple SAP technologies.

- SAP Business Technology Platform:

Serves as the cornerstone by offering a cohesive development and deployment environment. BTP makes it possible for different SAP services and apps to integrate and connect seamlessly.

- Plant Master Data:

Provides centralized access to details about the manufacturing plant, such as production lines, equipment, and environmental data. Analytics, optimization, and decision-making are all built on top of this data.

- Auto Defect Detection:

This feature uses computer vision and Internet of Things sensors to instantly detect flaws in products as they are being manufactured. This improves overall production efficiency, guarantees quality control, and lowers waste.

- Predictive maintenance:

This technique uses machine learning algorithms to anticipate equipment malfunctions before they happen. The system can plan maintenance proactively to reduce downtime and maximize resource utilization by evaluating sensor inputs and historical data.

- Plant 360 and Planning:

Offers an all-encompassing perspective of the manufacturing plant’s activities. Better decision-making, resource planning, and production process optimization are made possible by combining real-time data from multiple sources.

This adds AI functionality to the system and makes it easier to do advanced analytics, machine learning, and smart decision-making. Predictive maintenance, auto defect detection, and plant performance are all improved.

- SAP Analytics Cloud:

Provides a powerful analytics platform that facilitates the visualization and interpretation of data sourced from various sources. Data-driven decision-making for ongoing improvement is made possible by SAC‘s real-time insights into manufacturing processes.

- SAP HANA Cloud:

Provides high performance and scalability as the cloud computing platform and database. It facilitates real-time analytics, data processing, and integration for the whole smart factory ecosystem.

With the help of data-driven insights, predictive capabilities, and advanced analytics, this architecture builds a sustainable smart factory ecosystem that improves operations, lessens environmental impact, and promotes more effective and sustainable manufacturing practices.

Benefits of this Smart Factory App

- Reduced energy consumption

- Extended lifetime of machinery

- Reduced operational and maintenance costs

- Reduced risks of mishaps

- Improved production efficiency

- Reduced production disruption

- Reduced price of end products

Call-to-Action

AI in Action: Sound-Based Predictive Maintenance is a game-changing book that shines in the dynamic field of industrial maintenance. It introduces a proactive approach to equipment maintenance, reducing downtime and increasing performance by using artificial intelligence to decode machinery sounds.

It is critical to select the appropriate implementation partner as industries compete to stay ahead of the curve. Now introduce yourself to KaarTech—the pinnacle of AI innovation and competence.

KaarTech stands out as the perfect implementation partner with 18+ years of SAP expertise for businesses starting the journey of sound-based predictive maintenance because of our demonstrated track record of integrating cutting-edge technologies seamlessly.

Select KaarTech as your implementation partner and let your industrial assets’ unmatched longevity and efficiency be orchestrated by the symphony of AI-driven maintenance.

To learn more, check out our latest blog!!

FAQ’s

How does sound-based predictive maintenance differ from traditional methods?

Sound-based predictive maintenance relies on AI algorithms to analyze equipment sounds, detecting anomalies and predicting issues before they occur, offering a proactive approach that contrasts with reactive, scheduled maintenance in traditional methods.

What types of equipment benefit most from AI-driven predictive maintenance?

Complex machinery with intricate components, such as industrial turbines, manufacturing equipment, and advanced electronics, benefits most from AI-driven predictive maintenance, ensuring optimal performance and minimizing downtime.

Can AI accurately predict maintenance needs based on sound patterns?

Yes, AI analyses sound patterns to accurately predict maintenance needs by identifying deviations from normal operating sounds, enabling proactive intervention and preventing equipment failures before they occur.

What advantages does sound-based predictive maintenance offer over other approaches?

Sound-based predictive maintenance excels in early fault detection, enabling proactive intervention. It surpasses traditional methods by capturing nuanced acoustic signatures, offering real-time insights, reducing downtime, and enhancing overall equipment efficiency and lifespan.