Digital Transformation in Downstream Oil and Gas Industry

Introduction

The downstream operations of oil and gas companies, including refining and petrochemicals, have always embraced technology to enhance their operations. However, the advent of digitization has opened new possibilities for transforming these operations in a fundamental way. The potential benefits of adopting digital transformation in downstream oil and gas industry are immense, from reducing operating costs and improving throughput to enhancing health, safety, and environmental performance. This blog puts forth an effective framework for digitizing downstream operations in oil and gas, based on insights from collaborations with industry leaders.

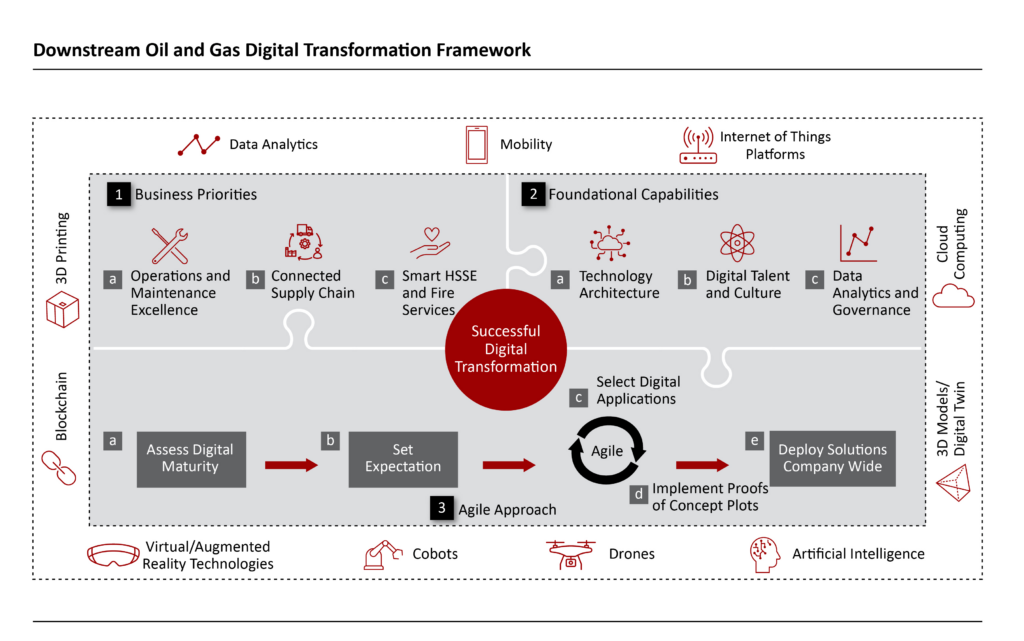

The framework consists of three integral components:

- Connecting digital initiatives to clear business priorities

- Building critical digital capabilities

- Adopting an agile approach to implementation

By following this framework, oil and gas companies can drive a technology-driven transformation in their operations.

Benefits of Digitizing Downstream Operations

- Reduce expenses by 10-20% through optimized, automated processes

- Increase throughput and productivity by 5-15% with data insights and automation

- Boost efficiency by 5-12% with real-time asset connectivity and visibility

- Improve HSSE through proactive risk identification and mitigation

- Cut unplanned shutdowns by 10-25% with predictive maintenance

- Empower workforce with digital tools and real-time data

Challenges Faced by the Oil and Gas Companies

While the advantages of digitization are persuasive, oil and gas companies encounter common challenges in implementing digital transformation in their downstream operations.

- Lack of Clear Digital Strategy: Investing in tech without aligning with business goals yields poor outcomes and uncertain ROI.

- Organizational Hurdles: Traditional, slow project management methods impede agility. Adopting agile approaches is crucial for collaboration and swift implementation.

- Data Governance Issues: Challenges in data capture, cleaning, and visualization impede meaningful insights, constraining digitization’s potential.

- Cultural Barriers: Resistance to change and a digital skills gap among employees hinder the adoption of innovative technologies.

Overcoming these challenges necessitates a well-structured framework to steer downstream oil and gas companies toward successful digital transformation.

Digital Transformation in Downstream Oil and Gas: The Framework

This framework comprises three key components: linking projects to business priorities, building foundational capabilities, and applying an agile approach to implementation.

Linking Projects to Business Priorities

The first step in the framework is to prioritize digitization efforts by aligning them with the functions that offer the maximum value. This involves emphasizing operations and maintenance excellence, connecting the supply chain digitally, and adopting smart HSSE and fire services.

-

Prioritizing Operations and Maintenance Excellence

To achieve excellence in operations and maintenance areas, companies must tap into emerging digital solutions. Advanced technologies like mobile and handheld devices, digital twins, and automation tools offer promising solutions for operations and maintenance excellence. By prioritizing and integrating these digital tools into their operations and maintenance activities, downstream players can realize substantial gains in productivity, reliability, and cost-effectiveness.

Furthermore, predictive and prescriptive maintenance tools powered by artificial intelligence (AI) can help companies reduce maintenance costs, minimize downtime, and improve asset performance. Upgrading sensor systems and implementing real-time asset monitoring enable long-term operational efficiencies.

-

Building a Connected Supply Chain

Digitally connecting the supply chain is another key priority for downstream oil and gas companies. End-to-end integration, from raw material suppliers to customers, can significantly increase operational efficiencies, reduce inventory, inform product development, and enhance customer service.

Digital applications facilitate efficient management of invoices, orders, categories, and suppliers. AI-powered inventory management systems and track-and-trace capabilities provide real-time visibility and data analytics. A fully integrated network of warehouses ensures seamless workflow and improved material tracking.

-

Embracing Smart HSSE and Fire Services

Ensuring health, safety, security, and environmental (HSSE) compliance is of utmost importance in the downstream oil and gas industry. Companies can leverage digital solutions to enhance HSSE performance and mitigate risks effectively.

Advanced options, such as 3D digital asset data capture through drones and virtual or augmented reality technologies for training and walk-throughs, have gained significant traction in the industry. Building a digital twin of operations infrastructure can further minimize physical exposure to hazardous environments.

Advanced technologies are harnessed to fortify emergency response systems, automate compliance through e-permits, and employ innovative tools such as drones and AR/VR for precise asset data capture. These strategic digital integrations not only enhance overall safety but also facilitate proactive risk mitigation, ensuring a resilient and secure operational environment.

-

Integrating HVC into the Digital Framework:

High-Value Compliance (HVC) takes center stage in the downstream oil and gas industry’s digital metamorphosis. The integration involves deploying blockchain for transparent compliance records, employing real-time monitoring tools to ensure adherence to regulatory metrics, and integrating compliance and risk management systems for a comprehensive approach. This dynamic fusion not only ensures regulatory adherence but also positions companies for sustained success in the evolving digital landscape, reinforcing their commitment to operational integrity and compliance excellence.

Building Foundational Capabilities

In addition to prioritizing projects based on business objectives, downstream oil and gas companies must build the foundational capabilities necessary for successful digitization. These capabilities include

-

Revamping Technology Architecture:

To fully embrace digitization, companies should overhaul their technology architecture, either by replacing outdated systems with newer technologies or integrating fresh applications onto existing infrastructure. The key elements of an upgraded technology architecture include seamless connectivity, real-time monitoring, and fortified control room capabilities.

-

Developing Digital Talent and Culture

In the journey toward a successful digital transformation, the core lies in providing employees with indispensable digital skills and nurturing a digital culture. It is critical for companies to invest in targeted digital training programs, elevating the digital literacy of their workforce. Overcoming resistance to change and fostering a growth mindset stand out as essential steps in building a digital culture.

-

Harnessing the Power of Data and Analytics

Data and analytics capabilities are the backbone of successful digitization. Companies must invest in data scientists and establish partnerships with original equipment manufacturers to effectively leverage data. A robust data governance and management model should be in place to ensure data accessibility and enable data-driven decision-making. Additionally, cybersecurity measures must be implemented to protect critical operations and assets.

Applying an Agile Approach for Effective Digital Transformation

The final component of the framework involves adopting an agile approach to digital transformation. This approach allows companies to navigate the rapidly evolving technological landscape and harness the benefits of digitization more effectively. The agile approach consists of five stages

-

Assessing Digital Maturity:

Before embarking on the digital transformation journey, companies should assess their current digital maturity level. This evaluation aids in identifying areas where the company needs to lead, match competitors, or strategically minimize investments. Understanding digital maturity enables companies to develop a clear vision for transformative change.

-

Setting Expectations Based on Benchmarking:

To establish realistic expectations, companies should benchmark themselves against digital champions in their industry. Analyzing successful digitization initiatives in other markets provides valuable insights and best practices. This process helps companies recognize their own potential and align expectations accordingly.

-

Selecting Digital Applications for Implementation:

Guided by prioritized business objectives and benchmarking insights, companies can choose digital applications suitable for implementation. Developing a clear business case for each potential investment and assessing expected returns is crucial. The maturity of digital enablers, including data, technology architecture, and culture, should inform the selection of specific solutions.

-

Implementing Pilot Projects:

Instead of pursuing large-scale IT implementations that consume years, downstream oil and gas companies are advised to embrace an agile approach. Implementing pilot projects allows testing the viability and effectiveness of digital technologies on a smaller scale. Companies can evaluate results, learn from the implementation process, and make informed decisions about scaling up initiatives.

-

Scaling Up Successful Initiatives:

Once pilot projects have demonstrated their applicability and delivered the desired benefits, companies can proceed to scale up the initiatives across the organization. Deploying solutions company-wide captures the full benefits of digitization and signifies a commitment to sustained digital transformation. The continuous rollout of new solutions and technologies reinforces the organization’s cultural shift, ensuring digital transformation remains a top priority.

Conclusion

In conclusion, digitizing downstream operations in the oil and gas industry offers remarkable potential for cost reduction, efficiency gains, and heightened safety standards. A structured approach, prioritizing operations, fostering a connected supply chain, and embracing smart HSSE services, is crucial for success. Revamping technology, nurturing digital talent, leveraging data effectively, and ensuring cybersecurity form the foundational pillars for success. Through this strategic transformation, companies can position themselves for sustained success in the digital landscape.

With 20 years of expertise in digital transformation, KaarTech is equipped with SAP’s digital portfolio tailored for the oil and gas industry. We stand ready to guide your business through the challenges of the future, ensuring you remain at the forefront of the industry. Contact us at KaarTech for expert guidance on your oil and gas digital transformation journey. Also, explore our case studies and success stories here.

FAQ’s

Why is digitization important for downstream oil and gas?

Digitization unlocks immense benefits like cost reduction, efficiency gains, and improved safety standards, transforming operations fundamentally.

What challenges do oil and gas companies face in digital transformation?

Common challenges include a lack of clear strategy, organizational hurdles, data governance issues, and cultural barriers.

What does the digital transformation framework entail?

The framework focuses on aligning projects with business priorities, building foundational capabilities, and adopting an agile implementation approach.

What are the key objectives of digitization in this industry?

Prioritizing operations, fostering a connected supply chain, and embracing smart HSSE services are essential objectives for digitizing downstream oil and gas operations.