Why do you need Integrated Supply Chain Management?

In today’s rapidly changing business landscape, companies are constantly striving to meet the evolving demands and preferences of customers. Customer expectations have transformed significantly over the years, with a growing desire for customized delivery experiences, real-time visibility, and a wider variety of products. To stay competitive and meet these demands, businesses are increasingly turning to integrated supply chain management.

What is Integrated Supply Chain Management?

Supply chain integration is a comprehensive business objective that aims to connect all stakeholders involved in the creation, distribution, and support of a product or service. By seamlessly connecting suppliers, manufacturers, customers, and other parties, businesses can optimize performance and achieve operational efficiency.

The ultimate goal of supply chain integration is to ensure that all participants work together towards a common objective while improving overall supply chain visibility and transparency.

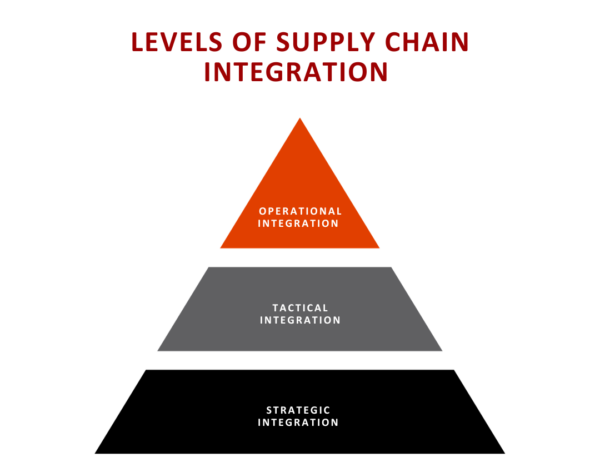

Levels of Supply Chain Integration

There are three levels of supply chain integration:

- Operational Integration

At the operational level, businesses focus on optimizing individual processes within the supply chain. This level emphasizes improving efficiency and effectiveness in specific areas without considering the impact on other processes. By streamlining and optimizing individual processes, businesses can enhance overall supply chain performance.

- Tactical Integration

Tactical integration involves integrating responsibilities and authorities across the organization. This level of integration focuses on controlling and designing the flow of materials at an organizational level and implementing information systems that span the entire company. By aligning processes and systems, businesses can achieve better coordination and decision-making.

- Strategic Integration

Strategic integration takes supply chain integration to a higher level by fostering partnerships, alliances, and relationships among supply chain members. This level involves designing and integrating inter-organizational information systems, processes, and collaboration at a supply chain level. By building strong relationships and partnerships, businesses can enhance supply chain resilience and responsiveness.

Advantages of Seamless Supply Chain Integration

Implementing supply chain integration can bring numerous benefits to businesses. Let’s explore some of these advantages:

- Enhanced Collaboration and Visibility:

– Facilitates seamless communication among stakeholders.

– 82% improvement in delivery timeliness through enterprise collaboration.

- Increased Revenues and Profit Margins:

– Optimizes processes for efficient product delivery.

– 25% boost in productivity, providing a 20% competitive advantage.

- Enhanced Customer Satisfaction:

– Real-time tracking and transparency for improved customer experience.

– Cloud-based integration correlates with a 35% increase in customer satisfaction.

- Increased Flexibility and Agility:

– Gathers data for adapting to market trends.

– Enables effective risk management and capitalization on growth opportunities.

- Waste Reduction and Sustainability:

– Eliminates duplication for improved resource utilization.

– Consolidates shipments and optimizes routes for cost and environmental savings.

Overcoming Challenges in Supply Chain Integration

While the benefits of supply chain integration are evident, there are several challenges that businesses may face when implementing integration strategies. Let’s explore some of these challenges and how to overcome them:

- Lack of Information Technology

Implementing supply chain integration requires the effective use of information technology. However, many businesses struggle with outdated or incompatible systems that hinder seamless integration. To overcome this challenge, businesses should invest in modern supply chain management software that enables efficient communication and collaboration among stakeholders.

- Lack of Information Sharing

Information sharing is crucial for supply chain integration, but many traditional supply chains lack a culture of sharing. To address this challenge, businesses should foster a culture of transparency and information sharing among stakeholders. Implementing robust information-sharing platforms and systems can facilitate real-time data exchange and collaboration.

- Lack of Trust

Trust plays a vital role in supply chain integration. However, trust can be lacking among stakeholders due to a lack of visibility and transparency. To build trust, businesses should establish clear communication channels, share performance metrics, and collaborate closely with suppliers, manufacturers, and customers. Building strong relationships based on trust and transparency is essential for successful supply chain integration.

- Demand Distortion-Bullwhip Effect

The bullwhip effect, or demand distortion, occurs when demand fluctuations at the end of the supply chain create amplified fluctuations upstream. This phenomenon can lead to inefficiencies, increased costs, and inventory imbalances. To mitigate the bullwhip effect, businesses should enhance demand forecasting accuracy, collaborate closely with suppliers, and implement demand-driven supply chain strategies.

- System Incompatibility

System incompatibility can hinder supply chain integration, particularly when different stakeholders use incompatible systems or technologies. Businesses should invest in end-to-end supply chain management solutions that offer compatibility across various systems and technologies. This ensures seamless integration and eliminates compatibility challenges.

- Lack of Knowledge

Implementing supply chain integration requires expertise and knowledge. Many businesses lack the necessary skills and knowledge to successfully integrate their supply chains. To overcome this challenge, businesses should consider hiring professionals with supply chain integration experience or partnering with experienced service providers who can guide them through the integration process.

- Cost of Integration

Supply chain integration may come with upfront costs, such as investing in new technologies or restructuring processes. However, the long-term benefits outweigh the initial costs. Businesses should carefully evaluate the potential return on investment and consider the long-term advantages of supply chain integration, such as increased efficiency, cost savings, and improved customer satisfaction.

Technologies Facilitating Supply Chain Integration

Several technologies can accelerate supply chain integration and enhance overall performance. Let’s explore some of these technologies:

- Robotic Process Automation (RPA)

Robotic Process Automation (RPA) can automate repetitive tasks and streamline supply chain processes. RPA software bots can perform tasks such as data entry, inventory tracking, and order fulfillment, reducing human error and increasing efficiency. By implementing RPA, businesses can free up resources to focus on core business activities.

- Blockchain or Distributed Ledger Technology (DLT)

Blockchain or Distributed Ledger Technology (DLT) provides a secure and transparent way to track and record transactions in the supply chain. By using blockchain, businesses can establish trust, improve traceability, and enhance security across the supply chain. Blockchain enables secure and efficient collaboration among stakeholders, reducing fraud and ensuring transparency.

- Extended Reality Tools

Extended Reality (XR) tools, such as virtual reality (VR) and augmented reality (AR), can revolutionize supply chain management. These tools can enhance design productivity, improve data visualization, and facilitate collaboration among global teams. For example, VR applications can enable teams to collaborate on project design and visualize complex data, leading to improved decision-making and efficiency.

- Artificial Intelligence (AI)

Artificial Intelligence (AI) plays a crucial role in supply chain integration by collecting and analyzing data from various sources. AI-powered analytics can provide valuable insights into market trends, customer behavior, and supply chain performance. By leveraging AI, businesses can optimize inventory management, enhance demand forecasting, and improve overall decision-making.

- 5G Networks

The implementation of 5G networks offers faster data processing and improved connectivity. With 5G, businesses can enhance real-time visibility tools, Internet of Things (IoT) capabilities, and overall supply chain agility. The reduced latency and increased bandwidth provided by 5G networks allow for more efficient communication and data exchange across the supply chain.

- Digital Supply Chain Twin

A Digital Supply Chain Twin (DSCT) is a computer representation of the physical supply chain that gathers real-time data from various sources. DSCT enables advanced analytics, simulation, and optimization of supply chain operations. By leveraging DSCT technology, businesses can improve supply chain performance, identify bottlenecks, and make data-driven decisions.

Integrated Supply Chain Management Solutions

To achieve effective supply chain integration, businesses can leverage integrated supply chain management solutions. These solutions provide a unified platform for managing and controlling all supply chain operations, from procurement to distribution.

Integrated supply chain management solutions cover pivotal functions:

- Supply Chain Planning:

Modern solutions streamline engineering and logistics, simplifying operations. They enable precise demand forecasting, optimized inventory, and transportation management, reducing complexities and costs.

- Transportation Management:

These systems consolidate transportation activities, ensuring comprehensive visibility and efficient accountability. Businesses cut costs, streamline operations, and boost transportation efficiency through integrated transportation management systems.

- Warehouse & Inventory Management:

Efficiently monitoring and analyzing warehouse activities is crucial. These solutions optimize storage, workforce utilization, and stock availability. They facilitate precise demand planning, enhancing overall supply chain performance.

- Global Logistics:

Navigating global trade complexities becomes manageable with integrated solutions. They offer insights for supplier identification, maintaining vendor relations, and efficiently managing global logistics operations. This facilitates market expansion and enhances supply chain performance.

Conclusion

In today’s competitive business landscape, supply chain integration is crucial for enhancing operational efficiency, improving customer satisfaction, and driving business growth. By connecting stakeholders, fostering collaboration, and leveraging technology, businesses can achieve seamless integration and gain a competitive advantage.

While there are challenges to overcome, the benefits of integrating supply chain far outweigh the costs. Businesses that invest this solutions, embrace technology advancements, and foster collaboration among stakeholders will be well-positioned to thrive in the evolving business environment. Integrated supply chain management is the key to unlocking operational excellence and staying ahead of the competition.

If you wish to integrate supply chain management for operational excellence, contact us at KaarTech.

FAQ’s

What is the primary goal of supply chain integration?

The primary objective is to seamlessly connect all stakeholders involved in product creation, distribution, and support. It aims to optimize performance, enhance collaboration, and ensure visibility across the entire supply chain.

How does supply chain integration benefit businesses?

Integrated supply chains offer improved collaboration, increased revenues, enhanced customer satisfaction, flexibility, waste reduction, and sustainability. These benefits stem from better visibility, efficiency, and the ability to respond to market changes effectively.

What challenges might businesses face when implementing supply chain integration?

Challenges include outdated technology systems, lack of information sharing and trust, the bullwhip effect in demand distortion, system incompatibility, lack of expertise, and initial integration costs.

What technologies facilitate supply chain integration?

Technologies such as Robotic Process Automation (RPA), Blockchain/Distributed Ledger Technology (DLT), Extended Reality (XR) tools, Artificial Intelligence (AI), 5G networks, and Digital Supply Chain Twins play pivotal roles in streamlining operations, enhancing security, improving decision-making, and fostering real-time connectivity across supply chains.